The UK Government extended the use of EU certified material and products in the UK. Therefore, the CE 3.1 material certificates are still valid for use alongside UKCA approval.

- For both CE and UKCA marking the boiler:

1) The WPS and welder quals need to be approved both by a EU Notified Body or EU RTPO, and UK Approved Body or UK RTPO.

2) The material manufacturers’ QMS (i.e. ISO9001 for the 3.1 certs for the main pressure bearing parts) need to have been audited by a competent body established with the EU and also a competent body established in the UK. However, for this year it is acceptable for both CE and UKCA marking that that material manufacturers’ QMS is approved by competent body established with the EU.

CE marking was permitted in the UK until the end of 2021. CE mark is required in the EU.

UKCA marking was required in the UK from start of 2021 (unless CE marked as above until end of 2021). UKCA mark not permitted in EU.

- To CE mark you will need an EU Notified Body

- To UK mark you will need a UK Approved Body

To comply with PED you need to have:

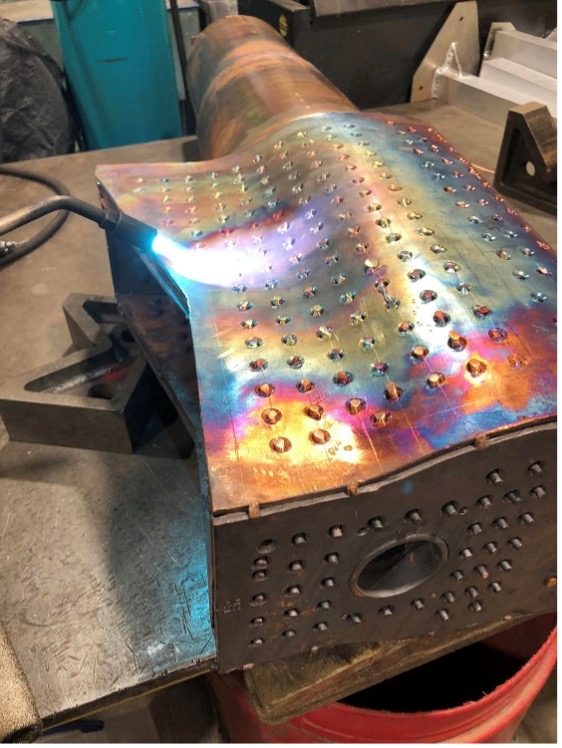

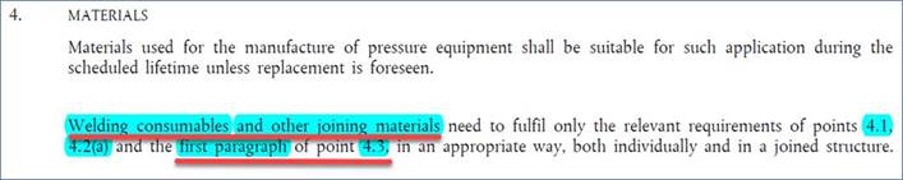

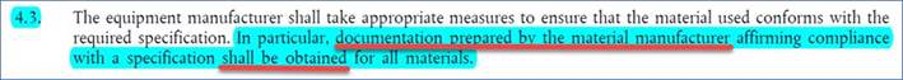

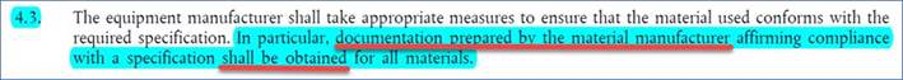

- 1. The material certificate from the material manufacturer. This is to comply with ESR 4.3:

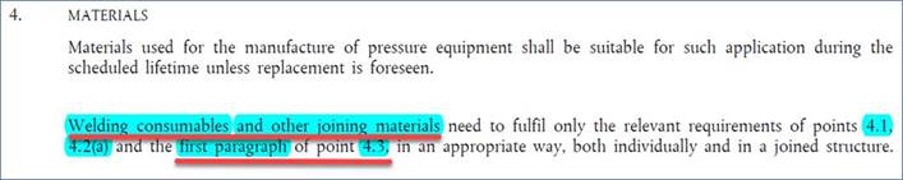

2. For welding/joining materials, this just needs to a EN10204 type 2.2 certificate, or the equivalent. (A 3.1 or 3.2 certificate is also acceptable). A type 2.2 certificate is a “Document in which the manufacturer declares that the products supplied are in compliance with the requirements of the order and in which he supplies test results based on non-specific inspection.”

2. For welding/joining materials, this just needs to a EN10204 type 2.2 certificate, or the equivalent. (A 3.1 or 3.2 certificate is also acceptable). A type 2.2 certificate is a “Document in which the manufacturer declares that the products supplied are in compliance with the requirements of the order and in which he supplies test results based on non-specific inspection.”

The words ‘non-specific inspection’ means “inspection carried out by the manufacturer in accordance with his own procedures to assess whether products defined by the same product specification and made by the same manufacturing process, are in compliance with the requirements of the order or not. The products inspected are not necessarily the products actually supplied.”

EN10204 allows an intermediary to copy the inspection document provided by the manufacturer, provided that the original document is available on request.

3. An independent inspector is called in to witness and take away samples for the following:

Welding procedure = EN ISO 15614-6:2006 welder qualification = EN ISO 9606-3:1999

Brazing procedure = BS EN 13134: 2000 brazer qualification = BS EN ISO 13585: 2012

These are tested in a UKAS accredited Lab for both NDT and DT and if compliance is met to the relevant standard we are awarded the qualification.

4. Then witness of a CAT II vessel is required by an independent body for UKCA showing test setup, design of vessel we intend to use, valid calibration of pressure gauge and all material and manufacturer certs are present.

Only then are we allowed to use our TPO number on CAT II vessels.

CAT I you only stamp UKCA and S.E.P. by law you must not stamp with UKCA.

When to mark:

Standard engineering practise < 2litres capacity not bearing

CAT I 2litres – 50 bar/litres

CAT II 50 bar/litres – 200 bar / litres

A handy calculator is available below

When not to mark:

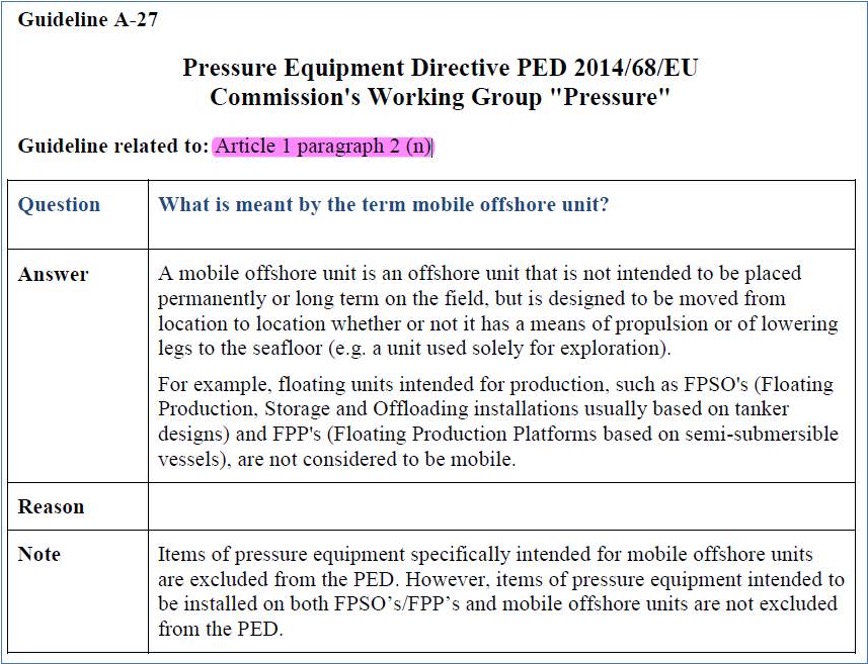

You can find all the exclusions under Article 1 paragraph 2 of the PED. If it is excluded, you don’t put the CE mark on it for PED, or a NoBo number.

What paperwork you should expect to see, CAT II Conformity certificate example:

UKCA Declaration of Conformity

Pressure equipment serial number:

Name and address of the manufacturer:

A company

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Object of the declaration:

Description: Live steam boiler for

Conformity Assessment procedure: Module A2

The object of the declaration described above is in conformity with the relevant union harmonisation legislation:

Pressure Equipment (Safety) Regulations 2016

Relevant designated standards used or other technical specifications in relation to which conformity is declared:

Designated Standards: EN ISO 15614-6:2006 EN ISO 9606-3:1999

BS EN 13134: 2000 BS EN ISO 13585: 2012

The name, address and number of the Approved Body which carried out the conformity assessment:

The fulfilment of essential safety requirements set out in Annex I has been demonstrated.

Signed for and on behalf of a company

Place of issue:

Date of issue:

Name:

Function:

Signature: